Feedback Devices - Resolvers

Resolver Specifications

| Model Option | -R |

| Model Description | Factory Mounted Resolver |

| Available Environment Options | All |

| Drawing Number | C/F |

| Compatible Motor | U-series, P-series |

| Transformation Ratio | .954 |

| Input Voltage (VRMS @ 5kHz) | 6.5 |

| Output Voltage (VRMS) | 6.2 ± 5% |

| Impedance ZSO | 1064 + j1647 |

| Impedance ZRO | 450 + j586 |

| Rotor DC Resistance (Ohms) | 83 |

| Stator DC Resistance (Ohms) | 143 |

| Maximum Accuracy | ± 7 arcmin |

Phasing Equation |

|

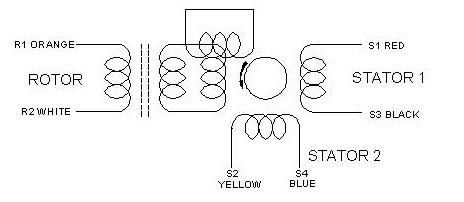

| E(S1-3) = K[E(R1-2)cos α] | E(S2-4) = K[E(R1-2)sin α] |

| Cabled Resolver Assignments (pairs) | ||

| R1: Green | S1: Red | S2: White |

| R2: Black | S3: Black | S4: Black |

Resolvers

Options

-ERD

ERD Manual (Rev E) (docx) (pdf)

ERD (with Pots) Tuning Guide (.docx download)

-Reference: RDE manual for previous product

Features

- Long cable runs supported, up to 500 ft.

- Rugged construction, protected mounting

- Good electrical noise immunity--twisted shielded pair cabling

- Compatible--connects easily to -RDE resolver-to-encoder converter

Feedback Devices

-Resolvers

Industrial working environments can be hard on position feedback transducers. Incremental rotary encoders are simple and cost effective in many motion control applications. However, encoders fail under extreme conditions such as high temperature, vacuum, radiation, or shock and vibration.

Brushless Resolvers Survive

Empire Magnetics makes resolver technology easy to apply with rugged motor-mounted resolvers and an easy to use resolver-to-encoder conversion module. Brushless resolvers and available with all Empire Magnetics motor products, providing shaft position information under harsh conditions.

Empire Magnetics mount optional size 11 resolvers on the back end of most Empire motor products, including gearmotors, and motors rated for submersion, vacuum, or radiation. Resolvers on environmental motors carry the same rating as the motors.